Operating using a hot tube, I always used a couple of layers of asbestos sheet as the insulator between the tube and chimney. SmokStak MESSAGE: (#1817) Some More Hot Tube Experiences, by: John C. Many a nickel tube has been ruined because of too harsh a gas flame, the inexperienced operator trying to keep his engines tube red hot without insulating between the tube and chimney. Also, the hot tube chimney needs to be lined with some type of insulation to reduce heat transfer and keep the tube red without damaging it. My suggestion is to experiment with length of tube at the desired RPM's you wish to operate your engine. Yet if the same engine is slowed down, using the same tube, it will knock considerably because more time is available between the firing of the charge and top dead center. When running at a higher RPM, say 250, a longer tube is used so the timing occurs enough before top center for optimum performance without knocking. Sometimes in stripping these old wells, I wanted to run the engines slow. Another thing to consider is the RPM's desired out of your engine. The length of the tube is critical, longer tube for advanced firing and shorter for retarded timing. įor many years I pumped crude oil up here in northern Ohio using S.M.Jones engines with hot tubes on powers. SmokStak MESSAGE: (#1796) Hot Tube Ignition, by: John C.

I know you will think all of the above sounds crazy but the timing of a hot tube engine works just the opposite of the way you think it should." The above is why the hot tube length is different for every engine. The piston has to really compress all the dead air and it takes more stroke for the good air/gas mixture to get to the hot spot. The shorter the tube the more retarded the ignition is. The longer the hot tube the more advanced the timing, the dead air goes up the tube faster and the air/gas mixture ignites quick. This is like retarding the spark and the engine is less violent when cranking it over. I start the engines just before the tube gets cherry red.

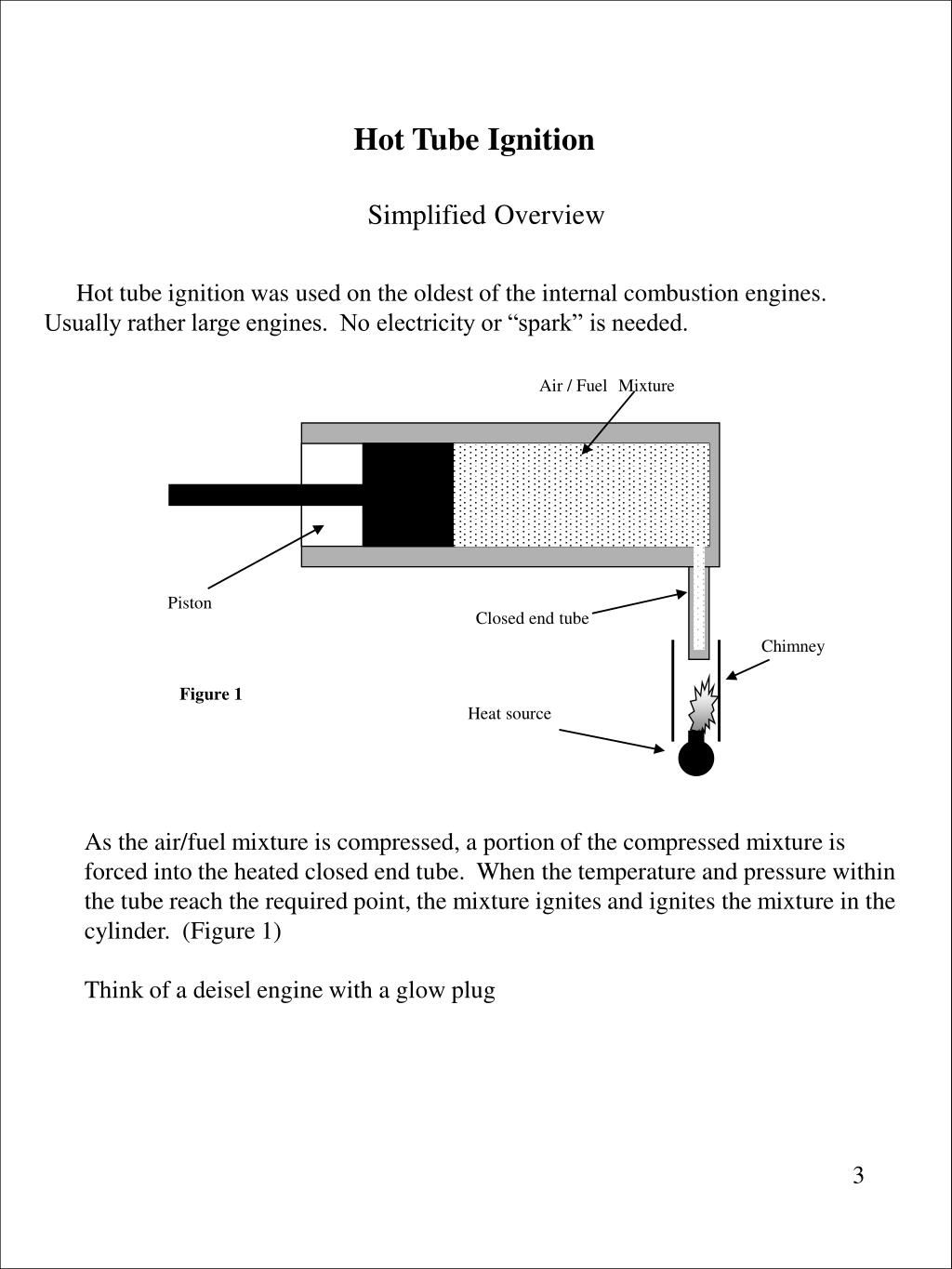

The dead air in the cylinder then goes up the hollow portion of the tube and when a fresh air/gas mixture hits the red hot spot in the tube it ignites under compression. "I run a couple of hot tube engines that I own and the timing is set by the length of the hot tube (the hollow portion inside the tube) and the amount of heat. The "reverse-start" method is most likely used, much the same as in Witte engines.Ĭraig Prucha wrote an email that explains his hot tube engine timing: I have seen some operators of these engines place a tin can over the outside chimney for added "insulation." The initial start-up must have been very difficult, perhaps instigating the "kitchen match" starting method used by Fairbanks Morse engines. We're talking about the 1890's here, before batteries were common.Īccurate timing is impossible with this method, other than its length from the combustion chamber and the amount of heat applied. Different lengths of tubes are used to effect the timing of the ignition. The outside portion of this tube is enveloped by a chimney to contain the applied heat from escaping to the atmosphere. When the compression stroke pushes the fresh fuel mix into the hot tube and it reaches the hot spot, ignition occurs. The ignition timing depends upon the degree of compression and the spent products of combustion from the previous cycle that remain in the tube. The HOT TUBE ignition is where a narrow capped tube that protrudes from the combustion chamber is heated red hot, blow torch style.

0 kommentar(er)

0 kommentar(er)